Our services

Penetrant Inspection / Crack Detection

Penetrant Inspection / Crack Detection

Maycast-Nokes offers two non-destructive testing (NDT) procedures; Radiographic Inspection and Liquid Penetrant Inspection.

Maycast-Nokes offers two non-destructive testing (NDT) procedures; Radiographic Inspection and Liquid Penetrant Inspection.

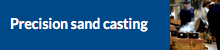

Penetrant Flaw Detection (PFD) is designed to identify any surface breaking defects such as cracks, laps or porosity. Our fully qualified Maycast-Nokes technicians are able to carry out complete surface inspection of castings and other metallic components.

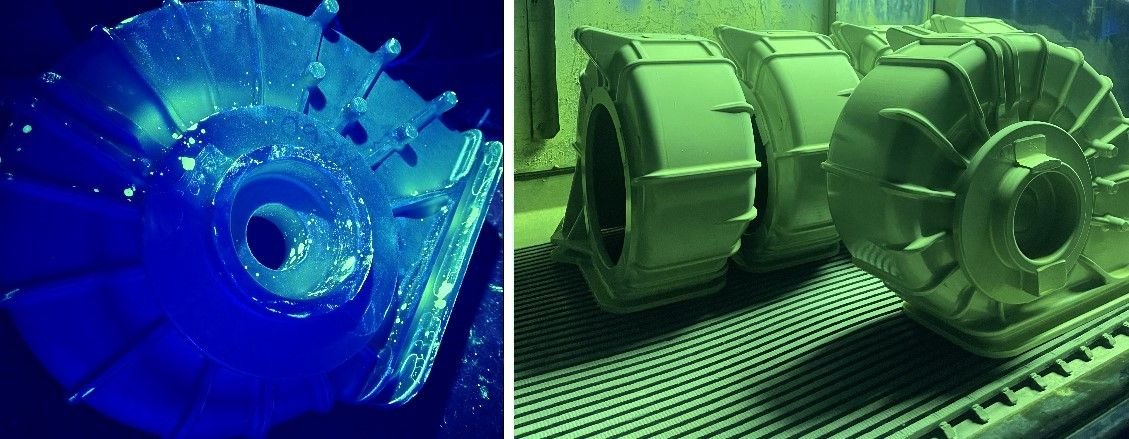

The principle of this testing method is that the dye/penetrant is drawn into any surface breaking defect by a process of capillary action. After a period of time soaking in the dye the castings are removed and rinsed. When viewed under ultra violet light any defect will 'bleed' with dye, indicating a possible defect. Castings are inspected against customer/national specifications and sentenced accordingly.

We employ multi-disciplined inspectors who are able to work in both NDT departments. All are qualified to NAS 410 / EN4179 + PCN level II. In addition to our Level II members of staff we also have an on-site Level III , who is qualified to write and sanction of our own process techniques without any assistance from an external source.

Both departments are fully Nadcap approved and are currently on the PRI Merit program (24 month audits) following eight previous successful audits.

Sub-Contract Testing Service

In addition to carrying out NDT inspection of our own castings Maycast-Nokes also offers a sub-contract NDT service, inspecting components manufactured by other companies to their required standards - please contact Tony Mays (tmays@maycast.co.uk) for further information.